Sheet metal fabrication cost understanding is crucial for prototyping. It is used to produce both initial and secondary articles, along with short production runs for components and finished products. However, the cost of sheet metal fabrication is one of the critical areas that prove to be challenging to product developers. Each process usually followed in the custom sheet metal fabrication entails an expense. These involve designing, prototyping, surface finishing costs, and materials to be used. Engineers estimate that the material cost alone comprises a large portion of the overall costs. Therefore, it’s important to have an effective and cheap way of handling your sheet metal fabrication project.

In this article, we will discuss the cost factors and give real-time examples of how to avoid these expenses. Let’s get into it.

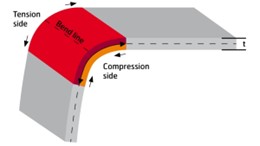

A basic understanding of sheet metal fabrication cost structures is crucial to approximate the cost. Sheet metal fabrication can transform your metal sheets into valuable products through a series of operations such as cutting, bending, punching, welding, roll forming, and many others. All of these phases factor in the overall cost of the undertaking in its specific area of focus.

Product development is actually done in various cycles which differ depending on the type of application. In order to be able to provide a realistic sheet metal cost estimate for each cycle it is necessary to reduce each of them to one step in order to make the work simpler.

Across costs, the material tends to incur high sheet metal fabrication costs. These may be metals, timber, or some other part. To estimate the material cost for one piece, multiply the volume by material density and cost per kilogram:

Formula:

Volume x Material Density x Material Cost Per Kg = Raw Material Cost of its product.

For instance, it’s assumed that the cost of material is $0.8 per kg while the density of steel is nearly equal to 7.4 kg/dm3. For a plate measuring 800 x 400 mm and 1 mm thick, the raw material cost would be:

Raw Material Cost = (8 x 4 x 0.01) x 7.4 x 0.8 = $1.89

It is advised to follow the same procedure for each material used in production.

The cost of machining comprises the hourly rates of the machine, its effectiveness, and time per cycle. The formula for calculating machining costs is:

Formula:

Efficiency = Hourly Cost x Cycle Time per Piece / Machining Cost

For example, if the cycle time is 12 seconds, efficiency is 85.5%, and the hourly cost is $78.4, the machining cost will be:

Machining cost = 78.4 x 12 / 855 / 3600 = $ 0.30

Thus, the total product cost for one piece will be:

Total Product Cost = Raw Material Cost + Machining Cost = 189+ 30 = 219 /– Total Product Cost = $2.

One of the largest components of manufacturing costs is the original materials which can be reduced greatly if the company applies itself to finding ways to do so.

Accurate determination of the sheet metal fabrication cost is imperative when you planning for a project. As a result of the latest advancements in technology, it has now become easier to trim down the overall cost of the projects. However, it’s still crucial to determine fabrication costs as accurately as possible. Let’s discuss the factors that influence sheet metal fabrication cost projects.

Installation implications are closely mirrored in sheet metal fabrication cost estimations by the time factor and the measure of installability. In some cases, installation is not part of the material costs, and it leads to higher costs.

Installation costs typically involve:

Material selection takes place right at the start of sheet metal fabrication cost. The price of materials increases and decreases as per market fluctuations. The greater the number of stages between a manufacturer and the raw material, the lower the transport costs will be. Moreover, metal thickness also has a bearing on materials and labor costs. If a project calls for several materials the cost will be higher, the same goes for situations where supply chains fluctuate.

Welding pre-plated sheet metal appears to be dangerous because when using heat to weld zinc releases as zinc oxide. Besides posing threats to the safety of these workers it also poses severe danger to the environment.

The cost of labor and the potential impact on plated sheet metal can affect the overall cost due to the time required for processing. Selecting uncoated steel and applying the coatings after the fabrication of the components will cause both equally – the cost and the time to rise. So, It is equally important to understand that by careful planning, it is usually possible to minimize welding and at the same time ensure cost-effectiveness.

The direct labor needed for metal fabrication, comprises welders, inspectors, and assembly technicians. The intensity of physical work affects the number of workers required for a particular project and thus their costs. CAD/CAM used in elaborate work to achieve precision also comes with the high costs of using professionals. Special equipment and tools are yet another important consideration.

The more complex the metal design involved, the higher the fabrication cost. If a design needs few cuts and bends then it will be cheaper to produce as compared to designs that feature many cuts, and wall thicknesses. Thus, superior tolerances and intricate designs mean increased costs of production. One might revisit designs for manufacturability (DFM) to compare the actual and potential costs of producing these designs and their quality.

Here are some tips to help you turn your project to cheap sheet metal fabrication, without compromising on quality, and functioning:

1. Select the Right Hides and Skins

The ability to choose the right materials can help you to save money. Raw materials that are normally easily obtainable are the most suitable to be used in stock. To reduce the cost of manufacturing, go for aluminum rather than stainless steel for the prototypes. When transitioning to the final fabrication cycle, prioritize parts that meet the required standards rather than focusing solely on the best materials. Other costs can be further reduced through purchasing mill-direct materials from fabricators that deal with suppliers directly as they get better prices due to bulk buying and efficient transport and warehousing.

2. Employ a Standard for Flat Stiffening

Many sheet metal fabrication costs can be reduced by utilizing standard sheet gauges and sizes. Custom lengths and thicknesses are likely to command a premium price. Therefore, to cut and bend materials and avoid increasing the costs as much as possible, the use of standard gauges should be maintained. Steer clear from special orders as often as possible since they are likely to increase manufacturing expenses.

3. Avoid Fancy Shapes & Designs

Products/components with the least amount of designs are easier and more economical to manufacture. For example, the angle bends should be desirable as simple angle bends with an inside radius of 1 times the material thickness. Do not incorporate complex elements into your design, including blind holes, machined pockets, or chamfered edges, if at all possible.

4. Finishing Options that have Lower Costs as one of their characteristics.

After fabricating the product, some may need specific surface treatments to enhance their endurance and appearance. For instance, chromium coating or anodic oxidation might incorporated, but they are costly and take time. Advised to avoid finishing such as engraving or silkscreening too early in the production process. Select affordable, easily obtainable finishes such as powder coating, passivation, and anodizing because they can be had for a reasonable price.

5. More Tips for Cost Reduction

Several other design considerations can help keep costs low:

6. Preventing TMI Syndrome in Sheet Metal Design

When you outsource your models to the manufacturer, it’s important not to flood your manufacturer with extra details. This information is normally incorporated by the designers together with information about the hardware or assembly components in a part being fabricated where it is not needed. Since it can hamper the estimating and manufacturing time.

7. Remember, Fast, Frugal Fasteners for Sheet Metal Parts

Appealing fasteners may look great, but they are expensive and time-consuming to implement in production. It is far cheaper to utilize common fasteners in the PEM catalog of fasteners. These fasteners are commonly warehoused and can be procured rapidly, thus cutting on time consumption. When ordering hardware such as aluminum or 400 Series stainless steel the available inventory may vary. Purchasing in large volumes such as 10,000 pieces, can cause an organization to have many hardware components around, increased costs of procurement, and long lead times.

8. Reduce Bending for Sheet Metal Components using Standard Fasteners

Certain sheet metal parts, like card guides used to support circuits, can be both costly and time-consuming to fabricate. Adjust your design to fit the standard components of an auto sales website. Although your team will need to include the guides, using off-the-shelf solutions can save both time and money. This approach is especially beneficial during the prototyping stage. It eliminates the need for costly tooling. The strategy helps keep sheet metal fabrication costs low and efficient.

9. Include Hardware BOMs

To prevent misconceptions and to ensure quick turnaround time, better is if you submit a Bill of Materials (BOM) when asking for a quotation on sheet metal parts. The list should keep the precise item that is going to be used in your construction like screws, nuts, or fasteners. It enables the manufacturer to know what specific names of the parts you want so that they offer the correct features (like threads) for those parts. In addition, adding a BOM helps save time and minimize communication issues with the manufacturer to provide the right part the first time.

When developing sheet metal parts, you need to quantify each substantial process involved in the fabrication process. You can moreover, optimize your sheet metal fabrication cost by opting for the tips aforementioned. Picking the right material, minimalism, and off-the-shelf hardware are some of the major strategies that can affect the cost of your project.

Furthermore, collaborating with professionals with sheet metal fabrication service providers will go a long way in reducing the designs and the costs. By having design for manufacturability (DFM) analysis and advice from experts, you can be in a position to have proper fabrication of sheet metal parts without immense cost while at the same time having the best performance.