Appearance and ergonomics are no longer the industrial design. It has incorporated functionality, manufacturability and optimum performance today. Designers should be able to design products that are easy to look at, strong, and cheap to make. It is here where the innovative motion is led through high-tech machining like custom CNC machining and CNC machining aluminum. CNC provides tight tolerances, finishes, and allowance with a variety of materials to provide a quick transfer between digital design and real-life physical by not compromising creativity, durability, or efficiency in the production processes.

To completely describe their contribution, we have to consider four basic features of material precision, rapid prototyping, functional integration, and production scalability. Combined, these factors reveal how CNC machining can take ideas and convert them into scalable and tried-and-true solutions that are used to modify modern industrial practices across the globe.

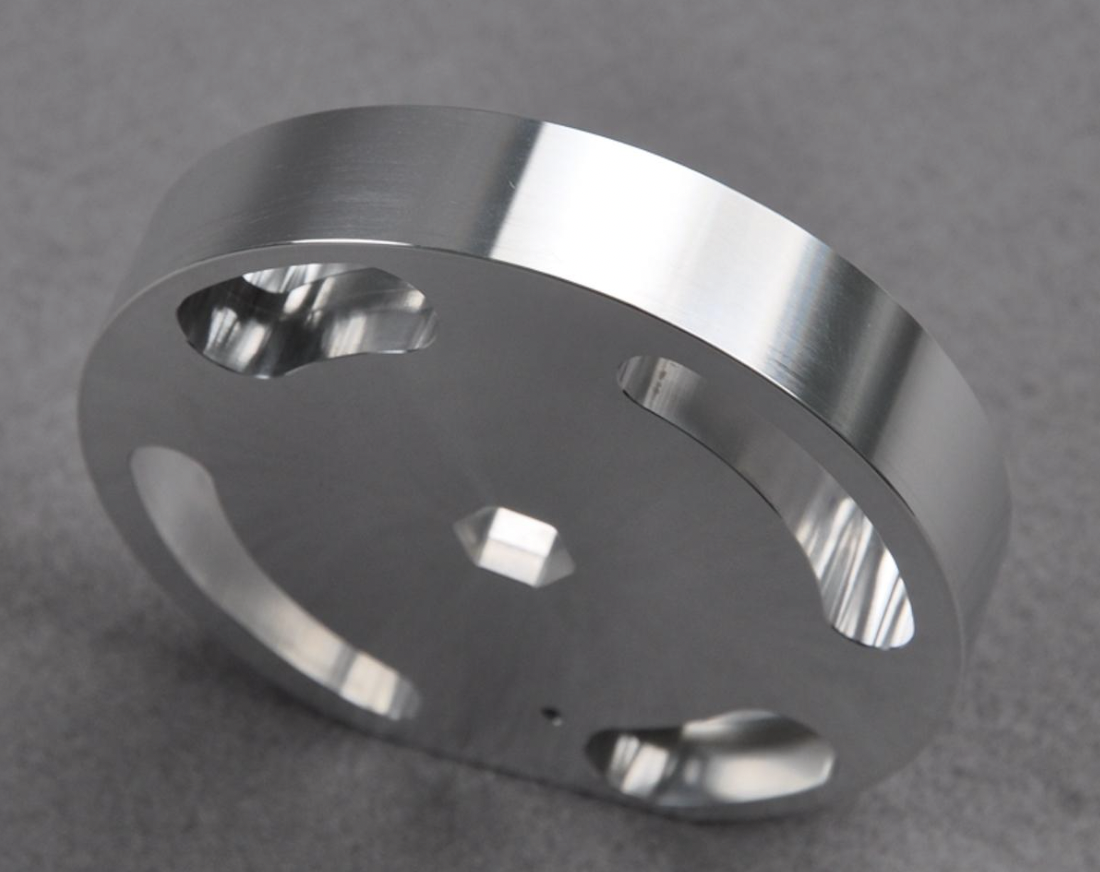

The choice of material is the most critical aspect of industrial design that affects the performance as well as aesthetics and durability. Aluminum has a relatively few weaknesses, largely related to its light weight, corrosion resistance and high strength-weight ratio, and consequently is generally favored use in several industries. Designers also get precisely machined components with ultra-clean surface finishes with CNC aluminum machining that could not be produced by traditional manufacturing processes.

Highly-engineered tooling, optimized feeds, and selected cutting parameters allow minimization of deformation and incredible geometry accuracy. Machining of complex features also ensures that even extremely complex assemblies can be frequently manufactured in a single solution, minimizing errors and lead times. In projects that require increased flexibility, custom CNC machining allows the use of multiple alloys, reinforced composites and hybrid substances and the new opportunities of innovation are available. This flexibility is an advantage in industries that need to balance performance with beauty, like consumer electronics and automotive and aerospace.

Since aluminum and CNC have the same level of machinability, and due to the flexibility of the latter, industrial designers can continually create parts that have exactly the right combination of form, functionality, and manufacturability.

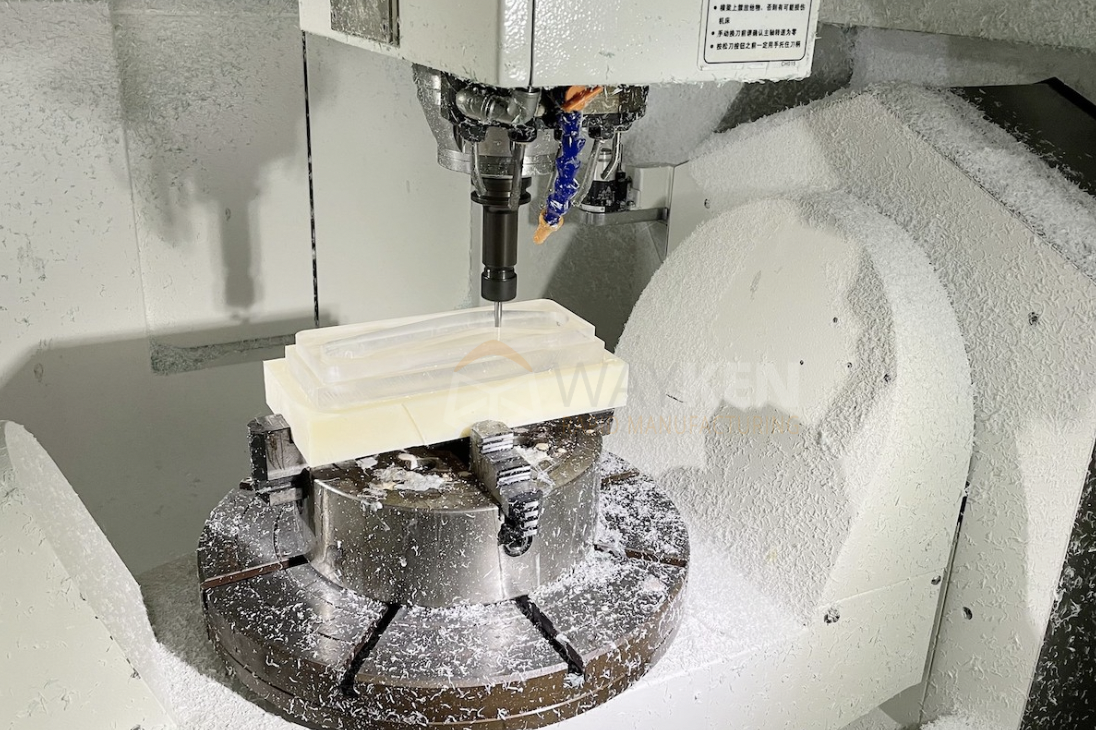

An industrial design can be defined by the feedback loop cycle in which concepts are cycled into working prototypes in the shortest practicable time. More conventional fabricating methods may find bottlenecks in this cycle, which slows the pace of experimentation and innovation. The challenge is overtaken by custom cnc machining that makes it possible to directly produce high accuracy prototypes and a digital cadenza map. The capability allows the engineer to have the opportunity to test ergonomics, assembly compatibility, performance characteristics without having to wait weeks before tooling was made or moulds were fabricated.

CNC aluminum machining boosts the speed with aluminum as the primary material. Fast spindles, optimized cut geometry and adaptive tool path has many-fold lead times and prototypes are created in days, not weeks. The resultant accuracy specimens are not only cosmetically representative, but also high in mechanical reliability, and thus could undergo testing in the real-world scenarios.

Such responsiveness can help designers to consider and compare more than one concept simultaneously, and optimize key factors, such as surface finishes, joint allowances and weight savings approaches. The shortening of the iteration cycle promotes innovation, minimize the total risk of the project and the ultimate result is a final product that promises to be more in line with the end-user's needs and requirements the market.

The main feature of the industrial design today is the smooth incorporation of a number of functions into a unit. The consumer electronics, robotics, and mobility device categories are increasingly using mechanical components, electronic circuits and thermal management systems in small and efficient packages. It takes machining processes that can create cavities and channels and mounting characteristics with peak preciseness without failure of the structure to achieve this degree of integration.

This can be achieved through custom cnc machining that produces geometries with highly specific functional requirements. Attributes of fastening, sensor enclosures, cooling, as well as electrical circuits can be simply integrated into the support structure. This minimizes use of secondary assemblies and minimizes the risk of misalignment or failure points.

In cases where aluminum has been chosen, cnc aluminum machining has an added benefit of being thermally conductive. Not only do aluminum enclosures and aluminum frames offer structural stability, they also make excellent natural heat sinks, eliminating heat produced by on-board electronics.

CNC machining enables both beauty and performance by incorporating these functions into the part itself. This combined solution will minimize system complexity, reduce the cost of production and enable the designers to produce products capable of fulfilling the two tasks of functionality and performance.

Any successful industrial design will ultimately have to move past prototypes and go into large scale, reliable manufacturing. This shift must be consistent, repeatable, and scalable since even a few dimensions can break product performance. The reason is that when performing custom cnc machining, the parts maintain their dimensional accuracy even when production is enhanced to thousands of parts.

Cnc aluminum machining offer a perfect compromise on stability and cost when it comes to scaling with aluminum material. The toolpath is optimized and automated workflows help minimize the cycle time as tolerance is controlled. All the parts are kept to the same high standard, irrespective of the quantity and the quality differences that normally arise in the traditional processes are removed.

This accuracy comes in especially handy in consumer electronics, mobile products and factory equipment where standardization is key to functionality and user safety. The connection between action-on-paper and high-volume production levels shortens the development timetable between concept and mass-market acceptance.

Precision, adaptability and repeatability enable designers and manufacturers to go between prototype till production without effect on quality of products ensuring they meet both functional/commercial requirements.

CNC machining has become a cornerstone of modern industrial design. From material precision to functional integration, it supports every stage of the design journey. Custom cnc machining delivers flexibility for unique requirements, while cnc aluminum machining ensures lightweight strength and production efficiency. Together, they enable faster iteration, seamless integration, and scalable manufacturing. Industrial design continues to evolve, and CNC machining remains at the center of this transformation, driving innovation with precision and reliability.