Metal fabrication plays a crucial role in modern industry, encompassing the creation and manufacturing of metal parts and structures through various processes such as cutting, bending, and assembling. Within this broad field, one might not immediately recognize the importance of seemingly minor components like metal caps. However, in industrial applications, these unassuming elements are essential for ensuring the protection and functionality of machinery, equipment, and systems.

Metal caps are protective coverings, typically fashioned from materials such as steel, aluminum, or brass. Their primary purpose is to cover or seal the end of a pipe, rod, or container, helping to protect against environmental factors, prevent contamination, and ensure pressure maintenance within systems. The fabrication of these caps requires precision and proficiency in metal working to ensure that they meet the stringent specifications and standards demanded by industrial operations.

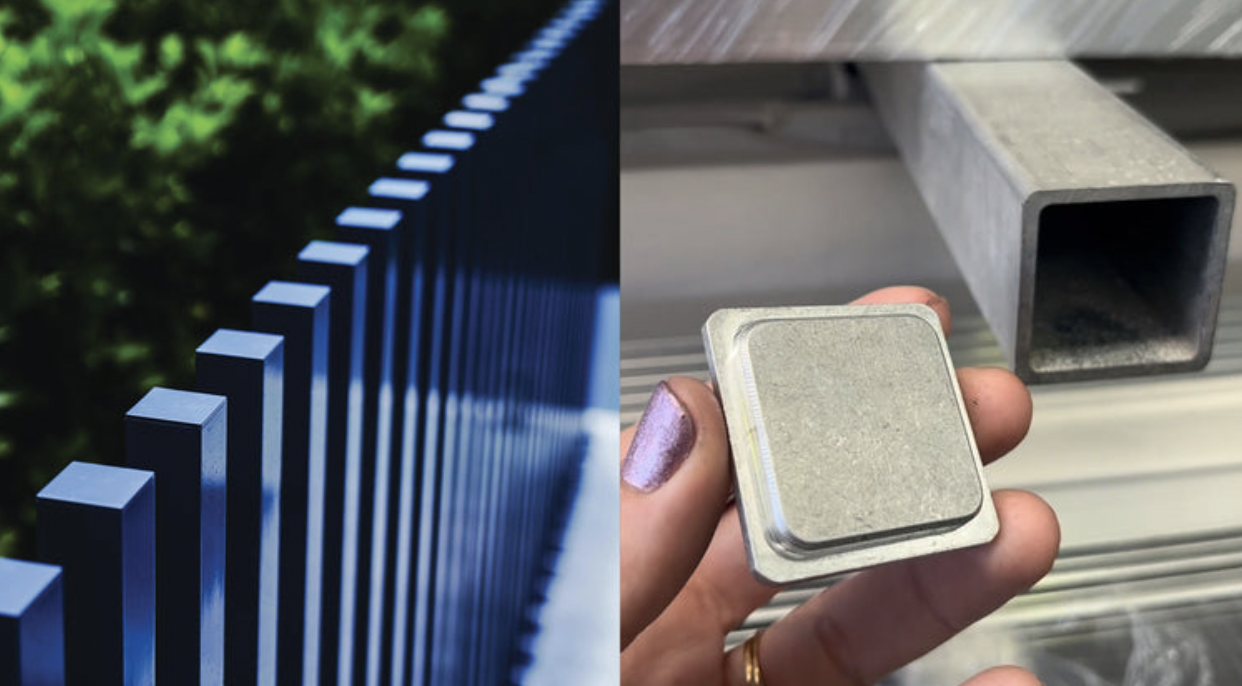

In the realm of industrial applications, there is no one-size-fits-all solution. Metal caps come in various shapes and sizes, each designed to fit specific requirements. They can be round, square, or rectangular, with each design serving a distinct purpose. For instance, round metal caps are commonly used to protect the end of pipes, while square or rectangular ones might be employed in machinery where corners are integral to the structure. Manufacturers need to offer customization options, enabling them to meet clients' unique specifications for dimension, shape, and material.

Producing high-quality metal caps involves several manufacturing processes. These can include stamping, wherein metal is shaped using a die; spinning, a process that uses a lathe to form metal into caps; or welding, for when caps require additional reinforcement. Advanced techniques such as CNC machining are also essential for achieving precision in measurements, particularly for components used in high-stakes environments like aerospace or petrochemical industries.

The use of metal caps extends across various industrial sectors. In the construction industry, they are vital for ensuring the structural integrity of beams and framing elements. In the oil and gas sector, caps play a crucial role in sealing off pipelines and protecting the internal contents from external contaminants. The automotive industry relies on these caps to cover parts such as fluid reservoirs and hubs, preventing leaks and maintaining performance.

Metal caps must be designed to withstand harsh conditions, including extreme temperatures, pressures, chemical exposure, and mechanical stress. The choice of metal for these caps will largely depend on the specific application and environment in which they will function. For example, stainless steel is often chosen for its corrosion resistance and strength, making it suitable for exposure to corrosive substances or outdoors.

Quality control is paramount in the fabrication of metal caps, given their critical nature in industrial applications. Diverse testing methods are used to ensure that they meet compliance with industry standards and certifications. This may involve pressure testing to assure their capability to withstand the required pressures and inspections to check for material defects and dimensional accuracy.

Manufacturers of metal caps face a variety of challenges, ranging from staying up-to-date with technological advancements to complying with environmental regulations. Supply chain management is another challenge, as sourcing quality materials can be difficult, and fluctuations in raw material prices can affect production costs. Furthermore, ensuring skilled labour in metalworking is essential to maintain the high standards expected in the industry.

With the advancement in industrial complexity, there is an increasing demand for custom metal caps tailored to the peculiar demands of new technologies and specialised equipment. Expert manufacturers need to collaborate closely with clients to design and fabricate metal caps that address specific issues, such as unusual sizes, special fitting requirements, or the need for integrated elements like threading or handles.

Innovation plays a significant role in the future of metal cap fabrication. As industries evolve, so do the needs for components that can perform under more demanding conditions or that contribute to making systems more efficient. The integration of new materials, the employment of cutting-edge fabrication techniques, and the inclusion of 'smart' features like sensors in metal caps are all potential areas for innovation.

It is clear that metal caps, although small and often overlooked, are integral to the safe and effective operation of countless industrial applications. Their production draws on a wide range of metalworking skills and technologies, with quality and precision being paramount. As industry advances, the manufacturing of these critical components will continue to adapt and incorporate new methods and materials, ensuring metal caps maintain their essential role in supporting modern infrastructure and technology.

Reliable and skilled metal fabricators, such as those at Nelson's CNC, are the backbone of this vital industry component. With their expert craftsmanship and attention to detail, they provide the essential parts, including custom metal caps, that industries count on to maintain and protect their vital systems. As the industry moves forward, the role of experienced fabricators in producing these seemingly simple but crucial protective elements remains indispensable.

Ultimately, the significance of metal caps in industrial applications cannot be overstated. They exemplify how intricate details and precision engineering work together to empower the larger mechanisms of industry. The fabricators who produce these items uphold a tradition of excellence that is as important as it is perpetual, contributing to the steady advancement and innovation within industrial sectors worldwide.