When laboratories prepare specimens for tensile testing, accuracy in geometry is essential. Even small variations in size or surface finish can lead to inconsistent results. That is why many facilities turn to finding the right cnc machine for tensile sample preparation as part of their workflow. These machines provide the repeatability and precision required to meet international testing standards.

CNC technology allows samples to be prepared with tight tolerances and smooth finishes, reducing the risk of irregular data. Depending on the type of material and the purpose of testing, labs may need either flat or round specimens. Flat specimens are often described as “dog bone” or “dumbbell” shapes, while round specimens are cylindrical with carefully defined diameters. Both types have specific applications, and the choice of machine often depends on which form is most common in the lab.

Tensile testing relies on two major specimen categories: flat and round. Flat specimens, sometimes called dog bone or dumbbell shapes, are commonly cut from sheet metal, polymers, or composite plates. Their geometry narrows in the middle section, where failure is expected to occur during testing. This design helps concentrate stress in a controlled area, ensuring that the measurement reflects the true properties of the material rather than edge effects. Many labs use flat tensile specimen preparation tools to achieve this geometry with high repeatability.

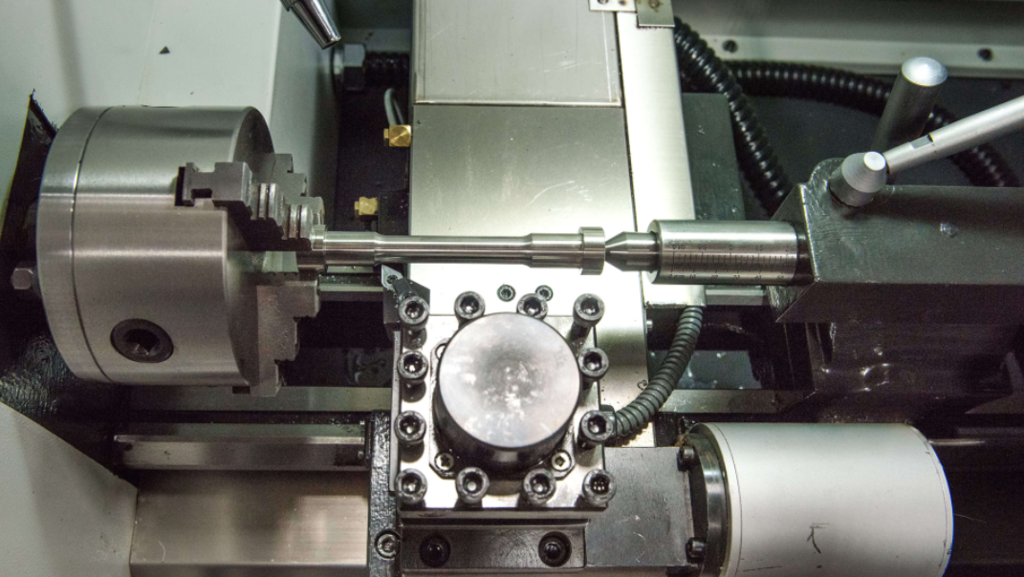

Round specimens are typically produced from bars, rods, or other bulk materials. These samples are machined to a uniform diameter with smooth transitions into the gripping areas. The cylindrical form provides consistency in stress distribution and makes it easier to calculate elongation and reduction of area. Round specimens are especially common in testing metals and alloys, where mechanical properties must be measured with high precision. In these cases, labs rely on machines for round tensile specimen prep to produce samples that match strict dimensional tolerances.

CNC machines for tensile sample preparation are designed to support both categories. They allow operators to produce flat or round shapes with repeatable accuracy, which is difficult to achieve using manual methods. By programming the cutting path and feed rate, CNC machining ensures that specimens comply with dimensional tolerances defined in standards such as ASTM E8 or ISO 6892.

Another important advantage is flexibility. A well-configured CNC system can switch between producing flat and round specimens without significant downtime, making it suitable for labs that test a wide range of materials. This adaptability is crucial when a laboratory handles both sheet products and bulk materials.

Understanding the difference between flat and round specimens is the first step in evaluating which type of CNC machine a lab needs. With clear knowledge of specimen geometry and the role it plays in tensile testing, decision-makers can better identify equipment that will consistently deliver standardized, high-quality results.

When preparing tensile specimens, consistency is the priority. Manual methods or general workshop machines often lead to small variations in geometry that can affect test outcomes. CNC systems, by contrast, are designed to reproduce exact shapes across multiple samples, which is vital for generating comparable data.

For flat specimens, especially dog bone or dumbbell shapes, CNC machining provides uniform edges and controlled thickness, which helps avoid premature failure outside the intended test area. The same applies to round specimens, where a smooth surface and precise diameter are essential for measuring elongation and strength. With cnc machines for flat tensile sample preparation, labs can rely on automated accuracy rather than operator skill. The same logic applies to cnc systems for round specimen preparation, where automation ensures that each sample matches strict tolerances required by testing standards.

Another reason CNC is preferred is efficiency. Once the machine is programmed, multiple specimens can be produced in sequence with minimal adjustments. This shortens preparation time, reduces the need for rework, and keeps workflows predictable. For labs working under accreditation or strict client requirements, this level of control is more than just convenient — it becomes necessary to maintain credibility.

Selecting the right CNC machine starts with the type of specimens the lab produces most often. A facility focusing on sheet materials will prioritize flat geometry, while one testing rods and bars will need reliable performance for round shapes. Machines capable of handling both can be valuable for labs with diverse workloads.

The next factor is compliance. Any chosen system should be able to prepare specimens in line with ASTM, ISO, or DIN standards. This includes the ability to achieve the correct gauge length, radius transitions, and surface finish. Without this, the risk of non-conforming samples increases, which can compromise both test validity and accreditation.

Ease of use also matters. A well-designed interface and straightforward setup allow technicians to work more efficiently, reducing training time and operator error. Maintenance is another point to consider: machines that offer accessible calibration routines and straightforward servicing help keep downtime low.

Finally, capacity and flexibility should guide the decision. Labs should assess the volume of samples they expect to prepare and the range of materials they will handle. Choosing a CNC system that balances throughput, precision, and adaptability will provide long-term value and support consistent testing performance.

Preparing tensile specimens is not just about cutting material into shape; it is about producing samples that meet standards and deliver reliable results. Choosing the right cnc machine for tensile sample preparation helps laboratories balance accuracy, efficiency, and long-term consistency.

By understanding the difference between flat and round specimens, recognizing why CNC systems are the preferred method, and reviewing the key factors before purchase, labs can make a decision that supports both daily operations and accreditation goals. A well-chosen CNC system becomes more than equipment — it is a foundation for dependable testing and trusted results.