When it comes to powering automation systems on an industrial scale, ease of operation, compactness, and reliability have become critical. SMPS has stabilized voltage while maintaining high efficiency and a small footprint, making it a preferred solution in industrial automation equipment. For B2B companies, optimization of operations can be achieved through proper component sourcing from a supplier for automation components, which ensures the performance and safety of the SMPS systems.

This document discusses the most important aspects of SMPS, its importance and powering automation and the importance of the correct supplier industrial efficiency.

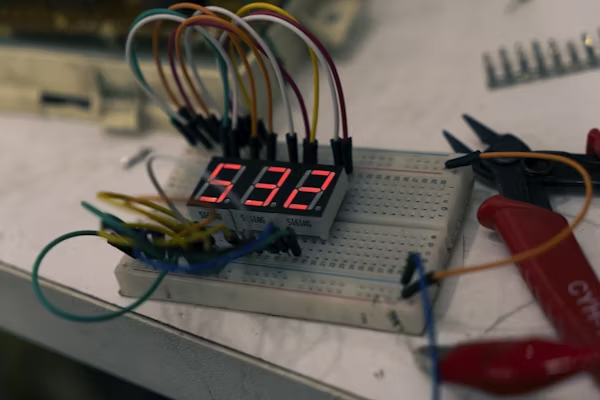

An SMPS is an electronic power supply that is able to convert electrical power in a mechanism that is deemed efficient through the use of switching regulators. Unlike the linear power supply which would get rid of the voltage that is in excess by dumping it as heat, an SMPS is able to get rid of the voltage while switching the input on and off and using energy storing components like inductors, transformers and capacitors to smoothen the voltage.

In industrial automation SMPS is extremely important for providing clean, stable power to delicate machinery, sensors, controllers, and even robotic arms. The main benefits of SMPS are shown below.

In the case of B2B companies, adding SMPS to automation systems saves on operational energy which with the increased reliability and reduced maintenance speaks to the long-term efficiency and lowered maintenance costs for optimal industrial functioning

For the purpose of selecting the appropriate model for industrial automation, the supporting structure of an SMPS, of which some are as follows, is essential to know. One SMPS is comprised of more than 2 items, the first one being;

Desired architecture allows the SMPS to keep high accuracy and dependability on the power even in extreme loads, which is beneficial for the purpose of industrial automation.

The automation of industrial equipment such as PLCs, robotic arms, and actuators involved, as well as the used powering systems, all require effectiveness to ensure smooth operation. With SMPS, industrial systems can easily be powered to maintain system voltage and support seamless operation. These include:

With minimal equipment downtime, high productivity levels can be achieved with the efficient and stable power provided by SMPS.

Every industry and business has specific features that influence core business processes. An industrial setting, for example, has high background temperature, high electrical noise, and equipment that works round the clock. These harsh environments SMPS encounters are serviced by its numerous benefits, such as

B2B enterprises benefit from the improved productivity and reduced maintenance costs that come with production. These factors lead to increased ROI for these businesses.

When sourcing an SMPS for industrial applications , finding a dependable automation component supplier is vital. A supplier will offer expert advice, product recommendations, and integration support before, during, or even after the sale. A few points to consider are:

The partnership with a contractor of choice helps the business save costs and time by picking the SMPS that will provide the highest efficiency and stabilization in their processes.

The efficiency of industries expands even more with the integration of SMPS into predictive maintenance features. Tracking of voltage and current, along with temperature and other fault finding monitors, are some of the most modern features of SMPS. These create the following opportunities:

System Optimization: Constant monitoring allows for precise adjustments to automation systems to improve energy use and operational effectiveness.

One possible synthesis of this is: Employing an SMPS in conjunction with a reputable automation component supplier makes sure industrial automation systems can perform predictive maintenance even while maintaining steady performance.

For B2B enterprises, acquiring SMPS from a reputable automation component supplier guarantees the appropriate choice, straightforward installation, and operational reliability over time. B2B enterprises can use SMPS to improve operational productivity by reducing energy expenditure, predictive maintenance that protects uptime, and enhancing equipment availability.

When B2B enterprises are equipped with high quality SMPS, the units support automation while reinforcing the competitiveness of the business. Other benefits that B2B enterprises can gain include system reliability and operational excellence.