Industrial automation focuses on a smooth flow of operations through efficacy and reliability of the systems. Micro switches and limit switches are among the most significant parts in the automation systems. Although these switches undertake the same roles of detecting mechanical movements and sending the signal to the system, they possess different features that cannot be used in a given kind of application. The article will enter into the distinction between micro switches and limit switches, their uses and also offer some suggestions on choosing the appropriate one that is best suited for you. The important influence of switching power supply manufacturers will also be considered as an addition to these vital elements.

A micro switch (or snap-action switch) is a type of switch that is highly sensitive in its operation and can be operated by a smaller than normal amount of force. Such switches are best suited in areas where there is need to be precise, fast, and reliable with regards to movement or change of position. Micro switches find their application in the fields of consumer electronics, security devices, domestic machine applications as well as in other low scale use. The most distinguishable feature of a micro switch is its response time which is speedy because of snap action, thus, the contacts can be closed or opened at a very fast rate using very little physical effort. Micro switches also come in many different designs such as subminiature design which can be fitted into small spaces. They are sensitive enough to sense the slightest movements in a setting that has a lot of importance to precision.

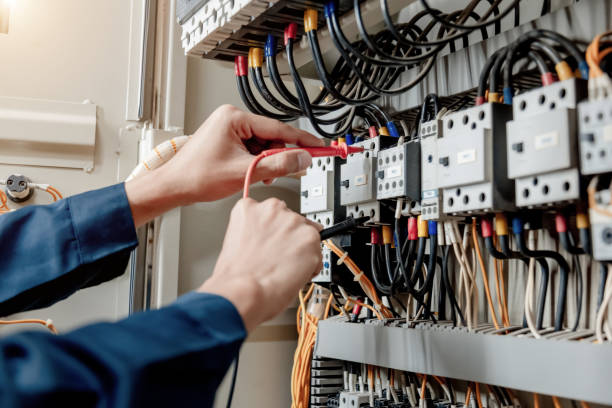

A limitation switch is an electromechanical instrument utilized to determine the situation of a dynamic component in a machine/system. The limit switches in comparison to the micro switches are bigger and more powerful and they are used to manage mechanical motions that are morequerySelector jercyro quantum in size. The practical application of these switches is in the industries, especially with the conveyor systems, the robotic arms and the elevators where the positioning of equipment is of essence. Limit switches are employed in order to disable or enable pieces of machinery when a specific mechanical limit is attained, and stop over-travel or a failure. They are very robust and designed to meet the harsh conditions of the industrial settings. Limit switches tend to be rustic compared to micro switches and provide capabilities with adjustable actuators and hermetically sealed housings to accommodate high loads and heavy applications.

Although micro switches and limit switches are effectively used for the same purpose, to detect movement and to control machinery, there are major differences between them which make them suitable in different areas. The micro switches are very sensitive, small, and small reaction time, hence very well suited in instances where little and correctly focused motion is to be detected. Applications where these switches are normally applied are those systems where minor mechanical variations occur e.g. home appliances and security units. Limit switches in comparison are more massive, sturdy, and they can sense greater movement. They can be utilized in industries where process control requires highly precise machineries e.g. industrial automation or robotics industries. Limit switches are constructed to handle greater mechanical forces and intended for heavy duty applications and are frequently required to operate under harsh environments such as dust, wet, high temperatures. Being aware of such differences, you would be able to select that switch which better suits the requirements of your system in terms of size, sensitivity and loading capacity.

Micro switches and limit switches need a constant and reliable source of power that will facilitate smooth functioning and operate efficiently. Here is where the dropping of switching power supply makers enters the equation. These manufacturers give the power solutions that allow your switches and other solutions to work effectively in your automation system. Switching power supplies change electrical power of one voltage into power at another voltage and with switching power supplies, you can be sure that the purpose of your power so as to use it on your system will have the appropriate power that the components will use in your system. As well as providing micro switch low-voltage supplies, switching power supply manufacturers also offer higher-voltage supplies to suit industrial applications such as limit switches. All are efficient, compact and reliable power supply sources that support most automation applications. This increases your switches to last long and perform adequately hence minimising chances of failure of your systems or inefficiency since you selected the correct power supply.

A switching power supply is also adjustable to fit well in the demands of an automation system making sure that your parts get provided with the right amount of current and voltage. This will enable you to streamline the efficiency of your network and reduce the power losses which is vital in industries when energy is a major factor to reckon with. As more and more industries need to embrace automation, seeking the services of known switching power supply companies can assist you in getting the most suitable ways of powering up the switches and other important elements in the automation system.

Micro switches and limit switches are important parts in the automation world and therefore used in specific applications due to their size, sensitivity and durability. Micro switches will suit best the consumer electronics, home appliances, and security, as this is where small, and precise motions are required, limit switches are strictly necessary in the industrial machinery and where industrial application demands more durability and tolerance of mechanical loads. By knowing the characteristics of the two kinds of switches, you may make sure that your automation systems have the appropriate components to guarantee reliability and performance.

The manufacturers of switching power supply, as well, cannot be disregarded in maintaining the system stable. Selecting a power supply that is appropriate to your switches and automation components will make sure that your components perform best hence making your automation systems successful in the long run. Either micro switches that apply in small scale systems, or the limit switches in heavy-duty industrial plants. Nevertheless, no matter what happens, it is important to make the correct decision. The more impressive the switches and power supply are, the more outstanding the performance and survival rates of your automated systems will be. By working with a reliable micro switch manufacturer, you can ensure that your micro switches are designed to meet the precision and reliability required in your applications. By the help of correct switches and power supply, a person can enhance the performance and reliability of the whole automation scheme i.e. enhance the production process and ensure sustainable development.