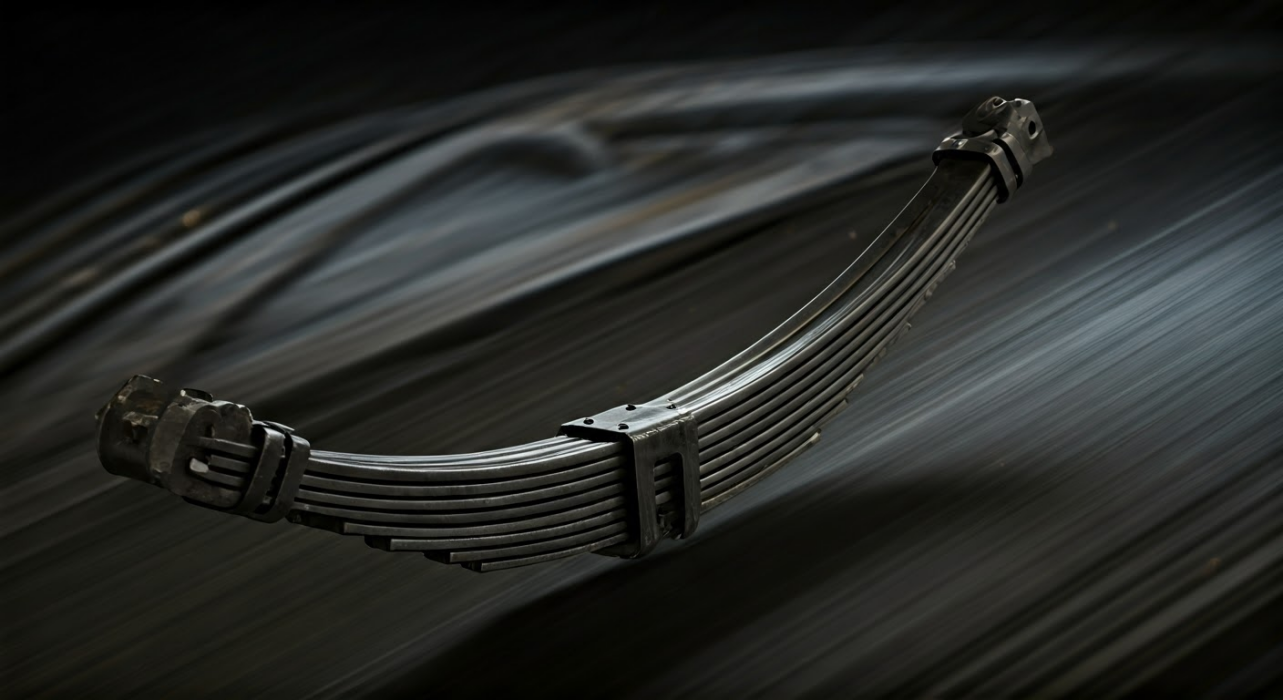

● Leaf springs are one of the oldest forms of vehicle suspension, widely used for heavy-duty applications like trucks, SUVs, and railway carriages.

● Commonly crafted from spring steel alloys such as SUP9, SUP11A, 5160, and 9260, they offer a balance of strength and flexibility.

● Composite materials are increasingly used for modern lightweight, high-performance leaf springs.

● Heat treatment processes enhance the durability, toughness, and fatigue resistance.

● Environmental conditions like corrosion and wear influence material selection.

● Proper design optimizes vehicle comfort, safety, and efficiency.

Leaf springs are made from spring steel that has the right amount of carbon. They are important parts of many vehicle suspension systems. These springs help provide flexibility, absorb shocks, and keep the chassis and axle aligned. Leaf springs come in different grades of spring steel, like SUP9 and SUP11A. They are used in many settings, from passenger cars to heavy-duty trucks. The carbon content is key for their durability and performance. That is why spring steel is a great choice for these components.

Leaf springs are made from different metals to fit various industrial and vehicle needs. Spring steel is the most popular choice. It has high strength and can resist wear well because of its ability to be treated with heat. In addition to steel, composite materials like fiberglass and carbon fiber are becoming more popular. They are light and resist corrosion.

Steel types such as SUP9, 5160, and 9260 are designed for tough vehicles like SUVs and off-road trucks. Composites help improve performance, especially in racing and electric cars, where being efficient is important.

Steel is essential for most leaf springs because it is strong and versatile. The kind of steel used—either plain carbon steel or stainless steel—depends on needs like how much weight it can hold and how well it stands up to the environment. For example, SUP9 steel is popular because it has a lot of carbon, making it tough and long-lasting. This plain carbon steel is perfect for passenger cars and small trucks.

Another common type is 5160 steel. It has a lot of chromium, giving it good corrosion resistance and great fatigue strength. This kind of steel is often used in SUVs and off-road vehicles that need to perform well in harsh conditions.

For jobs that need the best performance, stainless steel and advanced alloys like 9260 offer great strength and reduce wear over time. These kinds of steel meet the heavy load needs found in buses and industrial machines, showing their versatility across different areas.

Each kind of leaf spring metal has its own benefits and drawbacks based on what it's made of and how it is used:

SUP9 and SUP11A Steel:

● Benefits: These steels have high toughness. They work well in passenger and light-duty vehicles.

● Limitations: They can rust easily without extra protection.

5160 Steel:

● Benefits: This steel has great ductility and can resist fatigue. It's perfect for certain springs in off-road settings.

● Limitations: It's usually heavier, which can lower fuel efficiency.

9260 Steel:

● Benefits: This steel provides very high strength and performance. It can adapt well to heat treatment.

● Limitations: It's expensive to make due to its high alloy content.

Composite Materials:

● Benefits: These materials are lightweight and resistant to corrosion. They are great for performance vehicles.

● Limitations: They need special technologies to be produced.

Leaf spring design focuses on balancing strength and flexibility. This helps to handle road stress and heavy loads. Layers of spring steel or advanced materials are used, allowing the design to adjust to vertical movement while keeping the axle in place.

Each leaf is shaped carefully to ensure that the load is spread evenly across the chassis. Additional features include eyes for attachment and heat treatment improvements, like tempering, to make the spring last longer. Designers customize these features for different vehicle uses, boosting efficiency and safety without giving up performance.

Material properties like high strength and hardness are important for how well a leaf spring works under stress. Carbon steels are commonly used for springs. They can be made tougher with careful heat treatment. For big trucks, having a high carbon content makes the springs strong enough to handle heavy loads.

These springs are even better because they resist wear and changes from long-term use. Adding chromium and vanadium helps them fight off rust and makes them last longer, which is great for damp or salty industrial areas.

Composite leaf springs are different. They are very light but still perform well, which helps the vehicle go faster and save fuel. Their hardness comes from new engineering methods, making them dependable in tough situations.

Optimal leaf spring performance necessitates balancing durability with flexibility. Strengthened through heat treatments such as tempering, steel grades retain ductility and toughness essential for absorbing impacts. Below is a comparative table showcasing material traits:

Proper tempering of steel springs ensures maximum resilience, while composites rely on their engineering precision. From suspension systems in trucks to lightweight racing vehicles, durability and adaptability determine the ideal material configuration for optimal reliability.

In conclusion, knowing about leaf spring metals is important for anyone working on vehicle design, repair, or modifications. By learning about the different types of metals, their benefits and drawbacks, and the main features of leaf spring design, you can make better choices that improve performance and durability. Choosing the right materials not only impacts how the suspension system works but also affects the safety and comfort of the ride. Whether you are a professional or a fan, this information helps you get the most out of your projects and achieve better results. Keep an eye out for more tips and insights on materials and design in the automotive field!