Multi Jet Fusion (MJF) and Stereolithography (SLA) are two of the most advanced 3D printing technologies — but they serve very different purposes.

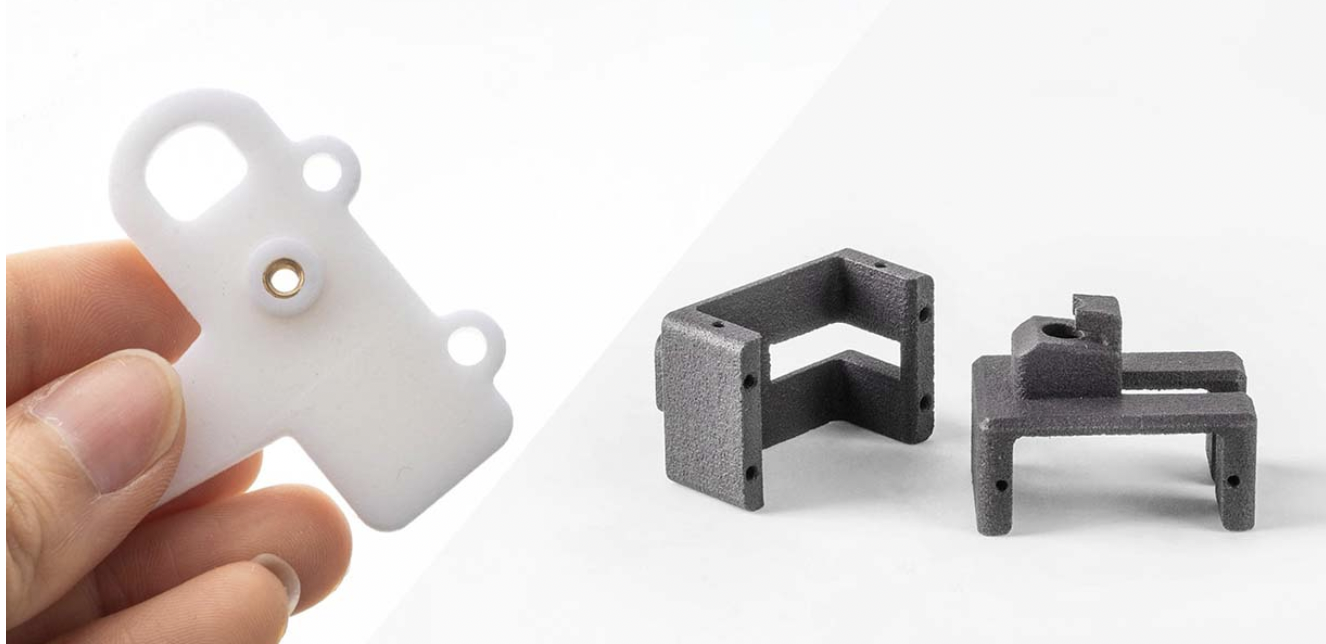

- MJF is ideal for producing functional, nylon parts with high strength and production repeatability.

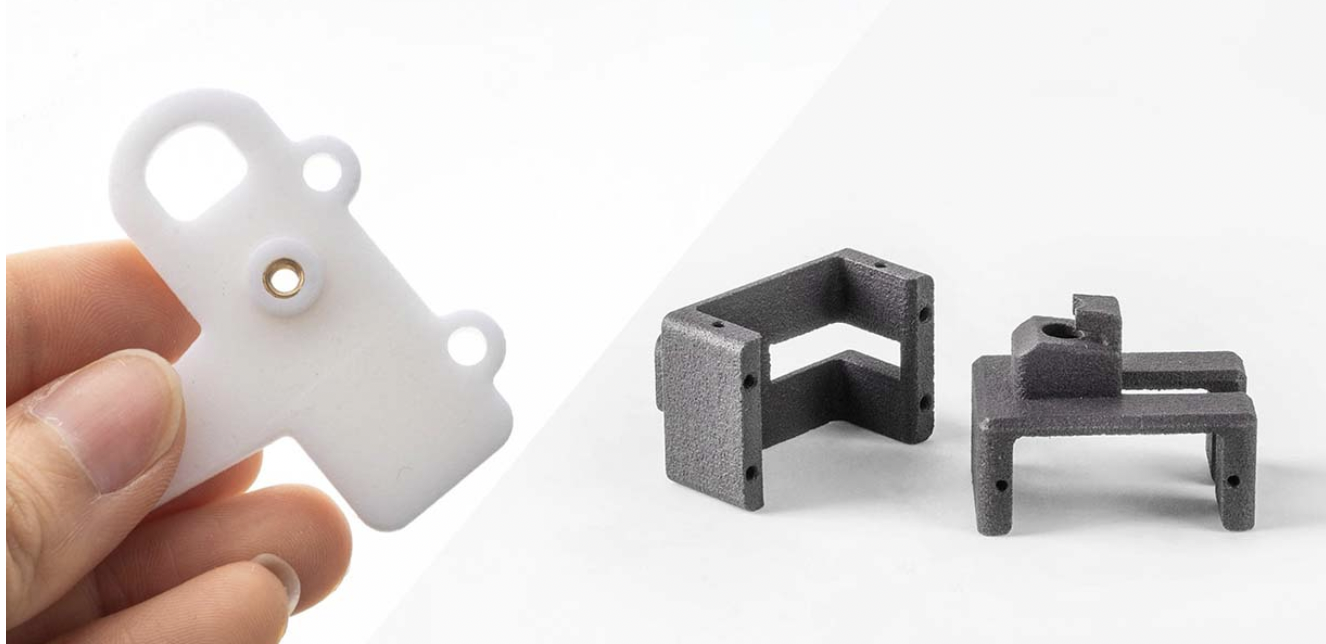

- SLA is the go-to for high-resolution, visually flawless prototypes, typically used for fit checks, cosmetic models, or molds.

This guide compares MJF and SLA in terms of materials, finish, accuracy, cost, and use cases — so you can select the best process for your needs.

🧠 What Is Multi Jet Fusion (MJF)?

MJF is a powder-bed fusion process developed by HP that uses:

- Nylon powder (typically PA11, PA12, or TPU)

- An inkjet printhead to deposit fusing and detailing agents

- An infrared lamp to sinter each layer in one pass

This results in strong, isotropic parts with good accuracy and a matte finish — ideal for end-use components.

💡 What Is Stereolithography (SLA)?

SLA uses a UV laser to cure liquid resin, layer by layer, into a solid part. The resin is held in a vat, and a build platform moves upward or downward depending on the printer design.

SLA produces extremely fine details and smooth, glossy surfaces, but parts are more brittle and UV-sensitive than MJF.

⚖️ MJF vs SLA: Side-by-Side Comparison

Feature | MJF (Multi Jet Fusion)

| SLA (Stereolithography) |

Material Type | Nylon powder (PA11, PA12)

| Photopolymer resin |

Strength | High, isotropic

| Brittle, non-functional |

Surface Finish | Matte, slightly textured

| Smooth, glossy |

Detail Resolution | High

| Extremely high |

Accuracy | ±0.003–0.010 in | ±0.002–0.005 in |

Durability | Production-grade | Cosmetic only (UV-sensitive) |

Support Structures | Not required | Required |

Post-Processing | Minimal | Requires washing, curing, cleanup |

Best For | End-use parts, short-run prod | Visual prototypes, fit models |

🎯 When to Use MJF

Choose MJF if you need:

- Functional, load-bearing parts

- Nylon materials with real-world durability

- Fast turnaround for small-to-mid production runs

- Clean finish and tight tolerances

- Complex geometries without support structure limitations

Ideal for: Housings, clips, brackets, jigs, functional prototypes, robotics, tooling components

🎨 When to Use SLA

Choose SLA if you need:

- A visual model or cosmetic prototype

- High feature detail (e.g., embossed text, sharp corners)

- A mold master for silicone casting

- A fast, affordable way to demo or showcase a concept

Ideal for: Presentation models, dental/medical replicas, jewelry patterns, early design iterations

🔍 Finish & Detail Comparison

Feature | MJF | SLA |

Finish | Matte black or gray | Smooth, glossy |

Feature Sharpness | High | Ultra-high |

Text & Logos | Crisp, readable | Micro-level detail possible |

Paintability | Yes (after priming) | Yes (very receptive) |

Custom Colors | Requires dyeing or coating | Tinted resins available |

🧪 Mechanical Performance

Property | MJF | SLA |

Impact Resistance | High | Low |

Fatigue Strength | High | Very low |

Heat Resistance | Good (PA12/PA11) | Moderate (can warp in heat) |

UV Resistance | Strong | Poor (resins degrade over time) |

💰 Cost Considerations

- SLA is cheaper per part for small visual models.

- MJF becomes more cost-effective for 10+ functional parts, especially when cosmetic finish isn’t the top priority.

Volume (units) | Recommended Process |

1–3 visual models | SLA |

5–500 functional parts | MJF |

500+ units | MJF (with scale pricing) |

🏁 Summary: MJF vs SLA

Use Case | Best Technology |

Functional plastic parts (end-use) | ✅ MJF |

Cosmetic or high-detail prototypes | ✅ SLA |

Snap fits, load-bearing, moving parts | ✅ MJF |

Clear parts | ✅ SLA |

Cost-effective small run production | ✅ MJF |

Display models | ✅ Either |

🏭 Get Expert Help Choosing the Right Process

At RapidMade, we offer both MJF and SLA printing — and we help engineers choose the best solution based on function, finish, speed, and scale.

Want help picking the right process for your part?

Get expert guidance and a custom quote at rapidmade.com