In the fast-paced world of textiles and materials science, efficiency, precision, and sustainability in research and development are non-negotiable. Traditional lab-scale professional clothes dyeing methods, while foundational, often grapple with lengthy process times, inconsistent results, and significant energy and water consumption. Enter a transformative solution: the InfraDye Infrared Lab Dyeing Machine. This innovative apparatus is redefining the benchmarks for sample dyeing, offering a leap forward in performance for quality control labs, R&D departments, and academic institutions worldwide.

What is the InfraDye Infrared Lab Dyeing Machine?

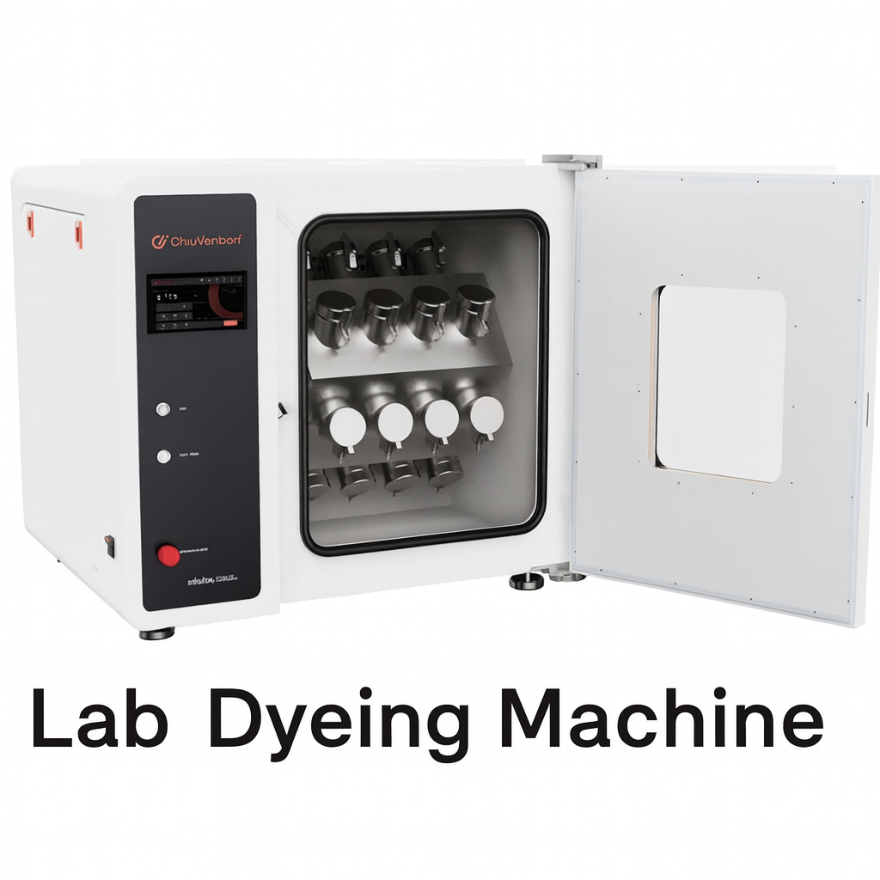

At its core, the InfraDye is a compact, state-of-the-art laboratory machine designed for dyeing and wet processing of textile samples, fibers, and yarns. Unlike conventional water-bath or convection-based lab dyeers, its revolutionary technology employs precise infrared (IR) heating to facilitate rapid and uniform thermal reactions. This shift from heating a large volume of water to directly heating the sample and its immediate liquor environment is the key to its groundbreaking performance.

How Does Infrared Technology Make a Difference?

The magic lies in the application of infrared energy. Here’s a breakdown of how it works and why it’s superior:

- Direct and Instantaneous Heating: Infrared radiation transfers heat energy directly to the dye liquor and the sample itself, bypassing the need to heat the entire metal vessel or a large water jacket. This leads to exceptionally fast heating rates—often achieving target temperatures in a fraction of the time required by traditional methods.

- Unmatched Temperature Uniformity & Control: The IR system, often coupled with advanced ceramic heating elements and precise PID controllers, ensures a perfectly uniform temperature distribution within each dyeing pot. This eliminates the "hot spots" and gradients common in older systems, guaranteeing batch-to-batch reproducibility and highly reliable, consistent results.

- Significant Resource Savings:

- Water: The system operates with a very low liquor ratio (the ratio of water/chemicals to fabric weight). Some models can function effectively with ratios as low as 1:5. This translates to a dramatic reduction in water and chemical usage per test.

- Energy: By heating only what's necessary and doing so rapidly, the InfraDye consumes significantly less electrical energy compared to a traditional lab dyeing machine.

- Time: Faster heating, dwelling, and cooling cycles drastically reduce total process time, accelerating project timelines and increasing lab throughput.

Key Features and Benefits at a Glance

- Rapid Processing: Cut dyeing cycle times by up to 50% or more, enabling faster decision-making and product development.

- Superior Reproducibility: Achieve consistent, reliable results crucial for pass/fail QC checks, formula development, and shade matching.

- Low Liquor Ratio Operation: Ideal for cost-effective and sustainable testing of expensive dyes and chemicals.

- Compact & User-Friendly Design: Saves valuable bench space and features intuitive controls, often with programmable memory for complex multi-step processes.

- Versatile Applications: Perfect for exhaust dyeing, bleaching, washing fastness tests, and other thermochemical wet processes on a variety of substrates.

- Enhanced Safety: Integrated safety features like over-temperature protection, lid locks during operation, and robust construction.

Who Should Use the InfraDye Machine?

This machine is an indispensable tool for any professional environment where textile color and finish are critical:

- Textile Mills & Dye Houses: For quality control, recipe formulation, and troubleshooting production dyes.

- Apparel & Home Furnishing Brands: To conduct lab dips for customer approval, test fabric performance, and ensure color consistency across supply chains.

- Chemical & Dyestuff Manufacturers: For developing and demonstrating new dye and auxiliary products.

- Academic & Research Institutions: For teaching textile chemistry and conducting advanced materials research.

- Third-Party Testing Laboratories: Providing fast, accurate, and auditable test results for clients.

The Bottom Line: A Smart Investment for the Future

The InfraDye Infrared Lab Dyeing Machine is more than just an upgrade—it's a paradigm shift. It addresses the core challenges of modern textile labs: the need for speed, unwavering accuracy, and sustainable practices. By drastically reducing resource consumption and process time while elevating result quality, it offers a rapid return on investment.

In an industry driven by innovation and sustainability, equipping your lab with infrared dyeing technology is a strategic move. It empowers your team to work smarter, faster, and greener, ensuring you stay ahead in a competitive global market.

Ready to transform your textile testing capabilities? Explore how the InfraDye system can be integrated into your workflow and begin a new chapter of efficiency and precision in your dyeing research and quality control.