Modern material handling systems must include belt conveyors since they economically and effectively move products across various sectors. Moving vast amounts of materials with little human involvement, these mechanical wonders simplify operations from mining and manufacturing to agriculture and logistics. Examining the significant parts, working concepts, kinds, and uses of belt conveyors is necessary to understand how they function. This understanding is essential to making the most of them, raising output, and guaranteeing safety in industrial settings.

What are Belt Conveyors?

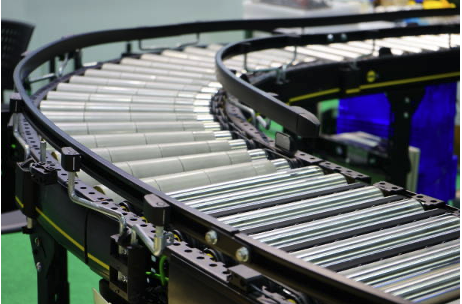

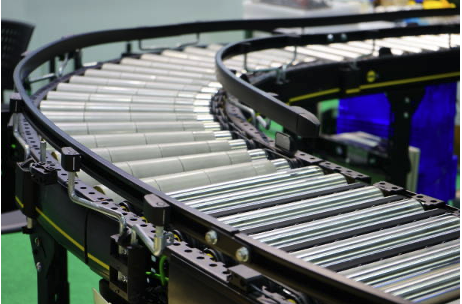

Belt conveyor is mechanical systems used to transport materials and goods over varying distances. They comprise a motorized pulley-driven continuous belt of rubber, PVC, or synthetic materials. The belt is aligned and supported in weight when traveling across several idler rollers.

These conveyors efficiently move bulk goods, packages, and products in manufacturing, mining, agriculture, and logistics industries. They are adaptable solutions for many material handling applications because they can be designed for horizontal, inclined, or curved courses.

Components of a Belt Conveyor

A belt conveyor’s operation depends critically on several vital components. The critical element is the belt, usually constructed of rubber, PVC, or other robust synthetic materials. The belt forms a continuous loop with the required motion supplied by a drive pulley.

The tensioning system ensures the belt is taut, preventing slippage and preserving efficiency, while the idler rollers support and keep the belt in alignment.

The drive system also comprises a motor and a gearbox, which provide the power and torque needed to move the belt. The frame or framework supports and aligns the whole assembly. Extra parts like scrapers and skirting systems are often added to control material spills and keep the belt clean. Knowing these parts is essential to understanding how belt conveyors work since each helps the system run smoothly and last long.

Image source - https://media.istockphoto.com/id/1237906763/photo/luggages-moving-on-airport-conveyor-belt-overhead-view.jpg

Operating Principles of Belt Conveyors

A belt conveyor works on basic mechanical concepts. The drive pulley, connected to a motor, starts the motion of the belt. As the motor turns, it rotates the drive pulley, which moves the belt.

The belt passes over the idler rollers, which keep it aligned and support the weight of the material being transported. The tensioning system keeps the belt at the proper tension, stopping slack and slippage.

Material is loaded onto the belt at the loading point and driven to the discharge point, where it is removed. This ongoing activity makes the adequate transportation of commodities over long or short distances possible. The belt can be steered in any direction or speed to suit specific operational requirements.

Belt conveyors are flexible for many applications, from moving large bulk materials in mining operations to moving light products in logistics facilities.

Types of Belt Conveyors

1. Flat Belt Conveyors

The most often used conveyor is a flat belt, which carries objects either slightly inclined or horizontally. Unit loads like boxes, bags, and other packaged products work well on these conveyors. Many industries, including manufacturing and warehousing, find flat belt conveyors simple and linear material-moving solutions. They are usually constructed of rubber, PVC, or other robust synthetic materials.

2. Trough Belt Conveyors

Trough belt conveyors are used for bulk material conveying. The raised edges of the belt provide a trough shape that holds loose materials and stops spills. Industries such as mining, agriculture, and construction frequently employ this conveyor where effective movement of goods like grains, coal, and ore is required. The long distance and rugged terrain operation of trough belt conveyors makes them appropriate for outdoor use.

Image source - https://media.istockphoto.com/id/1153054153/photo/conveyor-belt-curve-showing-brown-packed-postal-boxes.jpg

3. Incline/Decline Belt Conveyors

Incline and decline belt conveyors move materials between various elevations. These conveyors have rough surfaces or cleats on the belts to stop slippage and guarantee the products remain in position, going uphill or downhill. You’ll find incline/decline belt conveyors in food processing, packaging, and logistics industries, where products must be transported between floors or to different heights within a facility.

4. Modular Belt Conveyors

Modular belt conveyors use interlocking plastic segments instead of a continuous belt, offering flexibility and ease of maintenance. The modular architecture allows customization to particular requirements and simple replacement of damaged components. Because of their sanitary design, which makes cleaning simple and lowers the possibility of contamination, these conveyors are popular in food processing and packaging.

Image source - https://media.istockphoto.com/id/1199021421/photo/%D1%81ardboard-boxes-on-conveyor-in-warehouse-delivery-storage-and-distribution-service-concept.jpg

Applications of Belt Conveyors

Because belt conveyors are efficient and adaptable, they are used in many sectors. In the manufacturing sector, they streamline assembly lines by moving parts and finished products between workstations, reducing manual handling and increasing production speed. Often spanning great distances and over rugged terrain, the mining sector depends on belt conveyors to move mined minerals from mining sites to processing plants.

Belt conveyors in agriculture guarantee prompt and effective handling of harvested crops, seeds, and fertilizers. They improve order fulfillment speed and accuracy and benefit the logistics and

warehousing sector for sorting, packing, and shipping processes. Sanitary belt conveyors are also used in food processing facilities to transport goods from preparation to packing.

Further, belt conveyors guarantee the quick and effortless transfer of bags in airport baggage handling systems. The recycling sector also uses them to select and move recyclable products, promoting environmental sustainability. Belt conveyors’ flexibility in various settings and jobs emphasizes their significance in contemporary industrial processes.

Conclusion

Optimizing belt conveyor use across a range of sectors requires an understanding of their fundamental operation. Understanding their parts, working principles, kinds, and uses will help companies increase productivity, cut expenses, and raise safety. Modern material handling systems still heavily rely on belt conveyors.

Image source - https://media.istockphoto.com/id/1237906763/photo/luggages-moving-on-airport-conveyor-belt-overhead-view.jpg

Image source - https://media.istockphoto.com/id/1237906763/photo/luggages-moving-on-airport-conveyor-belt-overhead-view.jpg

Image source - https://media.istockphoto.com/id/1153054153/photo/conveyor-belt-curve-showing-brown-packed-postal-boxes.jpg

Image source - https://media.istockphoto.com/id/1153054153/photo/conveyor-belt-curve-showing-brown-packed-postal-boxes.jpg

Image source - https://media.istockphoto.com/id/1199021421/photo/%D1%81ardboard-boxes-on-conveyor-in-warehouse-delivery-storage-and-distribution-service-concept.jpg

Image source - https://media.istockphoto.com/id/1199021421/photo/%D1%81ardboard-boxes-on-conveyor-in-warehouse-delivery-storage-and-distribution-service-concept.jpg